SELECTING ROBOTIC POSITIONERS

![]()

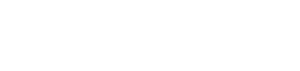

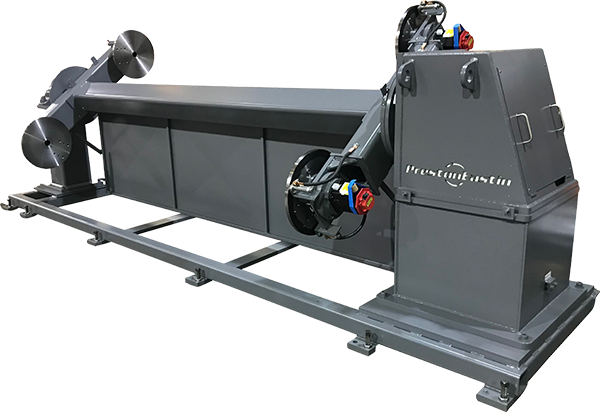

Most robots have six axes that can reach various regions of a part or assembly. While this sufficient for many applications, adding the right positioner exponentially expands your robotic capabilities. A positioner like a 5-axis positioner can present a simple or complex part to a robotic arm for repeatable welds. A Robot Transport Unit can move a robot around an assembly or part, which is why an RTU is also known as a 7thaxis positioner. A robotic positioner should be customized for your application, footprint, and part geometry, so that it can work in unison with a robot performing an articulated motion. The geometry of your part (e.g., capacity and size) and process (e.g., duty cycle) will influence which positioner(s) you select.