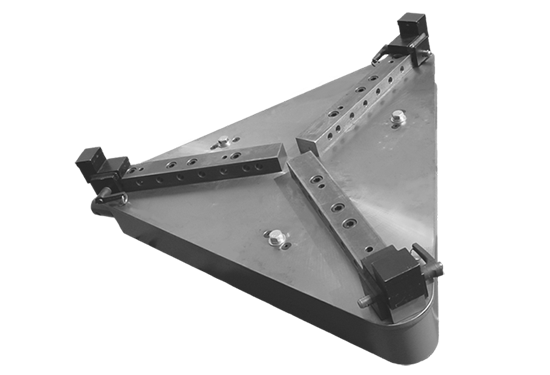

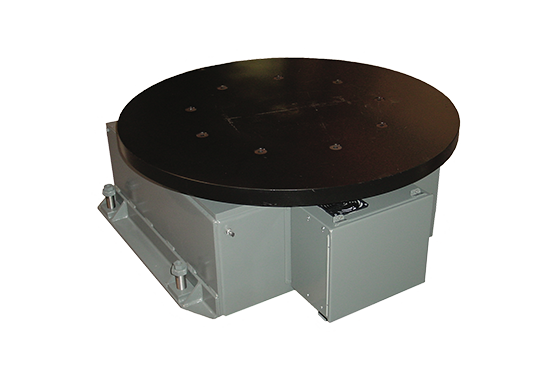

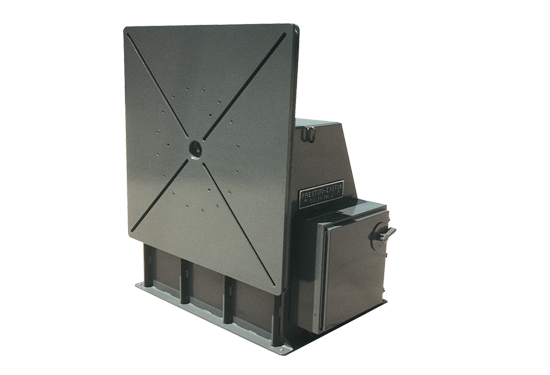

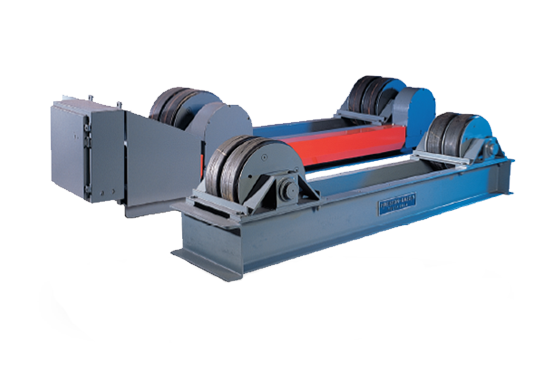

WELDING POSITIONERS

![]()

Our American-made welding positioning equipment lowers manufacturing costs and improves quality. We’re able to reduce welder’s fatigue and increase productivity by an average of 30%. This is achieved through fewer welding start-stops, faster deposition, less scrap, and superior ergonomics.

We have decades of experience making welding positioners, and we always work closely to understand your needs. We will customize your positioner to ensure you get the highest quality, most effective solution for your application.