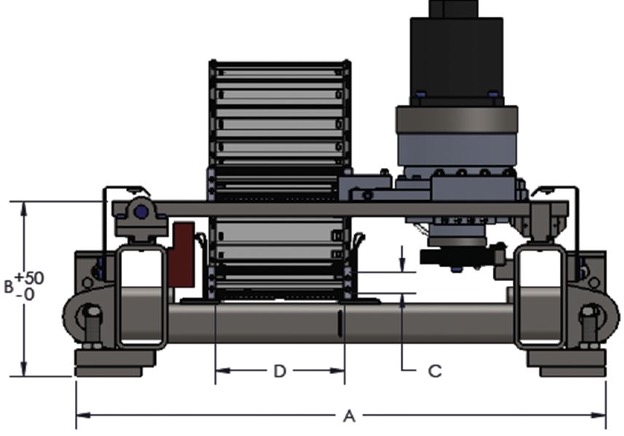

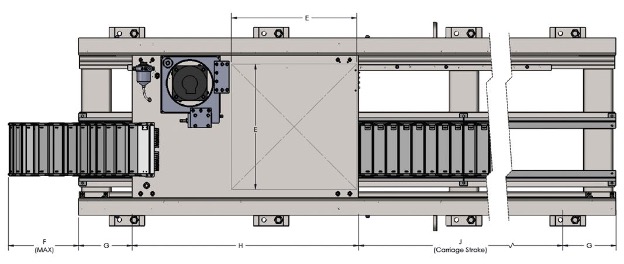

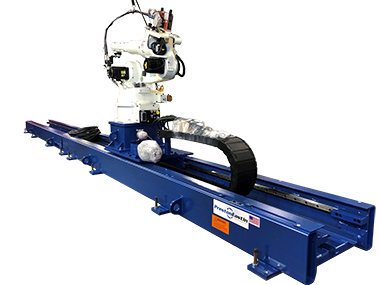

RTUs / 7th Axis

![]()

Our Robot Transport Units (RTUs) provide precise linear movement for robotic applications. Our unique design is customizable, scalable, and robust. Our rigid, low-profile RTUs distinguish us from our competitors, providing for low maintenance and reliable positioning solutions to maximize up-time. We’ve helped engineer systems to weld the next generation of electric vehicles, paint the wings of large aircraft, and fabricate the largest utility poles. We will craft an RTU of any length, for just about any mechanical operation.