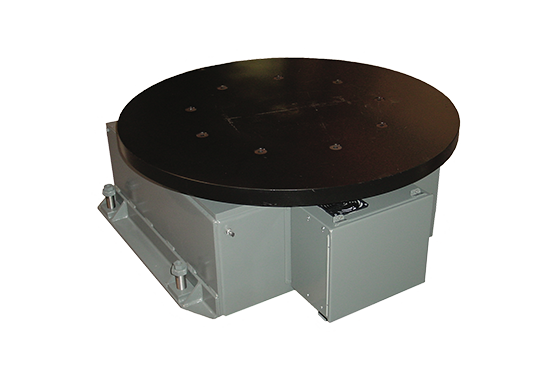

WELDING FLOOR TURNTABLES

![]()

Preston Eastin floor turntables are high-precision, low-cost welding positioners designed to rotate larger workpieces around a vertical axis. Each welding turntable is engineered to handle high capacities and speeds. We also offer anti-backlash solutions that retain fluid motion and precision during operation. They are ideal for welding, flame cutting, thermal spraying, grinding, painting, X-raying and drill press positioning. They offer increased accuracy, quality, and repeatability. Preston Eastin can fully customize your turntable with our below features.